Doppeltwirkender Hydraulikzylinder

Industrieausführung 250 bar // Baureihe: HZD5

General Information

Series HZD5 cylinders are double-action cylinders without end position damping, designed for difficult in-dustrial application conditions. During the design of this cylinder, we paid special attention to high functional security and stability, guaranteed through the use of high-quality materials. For seal maintenance cases, the rod-side bearing seat and the piston rod guide are designed to be screwable. The piston rod consists of high-tensile structural steel with an approximately 25 μm hard chromium-plated layer. Other materials and coatings are available on request.

Please consult us in case of radial forces and non-vertical installation.

Technical Information | |

|---|---|

| Maximal operating pressure | = 250 bar |

| Testing pressure | = 315 bar |

| Piston Ø | = 100 – 320 mm |

| Accepted temperature range of the hydraulic fluid | = -20°C up to +80°C |

| Hydraulic fluid | = mineral oil (HL, HLP) according to DIN 51524 & DIN 51525 (standard) |

| Stroke speed | = ≤ 0,5 m/s |

Length and stroke tolerances according to DIN7168g (see >>Technical Information)

Additional Information

Order Key

Click >> this linkto download the order key in PDF format.

Piston ≤ 200 mm

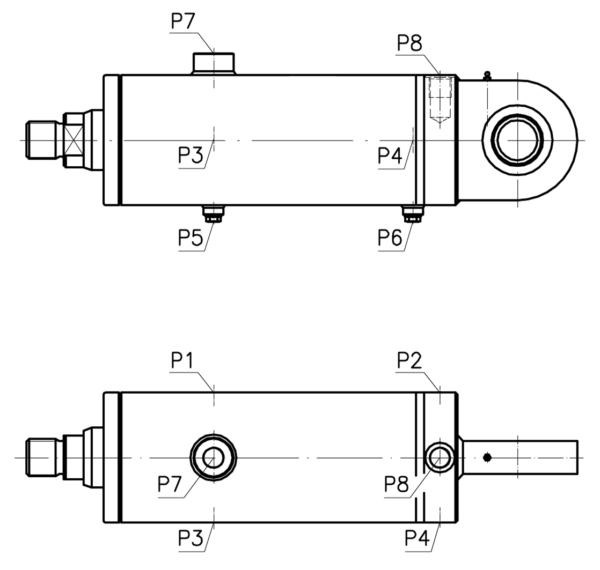

Position of the P5/P6 vents and the P7/P8 fitting≤ 200 mm

For long strokes, the support width of the piston rod in the cylinder tube can be changed in order to reduce the load on the guide system when fully extended. This also depends on the type of installation and the design of the cylinder.

D1 - Groove ring and scraper made of polyurethane and a compact seal (NBR) on the piston (standard) | |

|---|---|

| Temperature range | -30°C to +80°C |

| Hydraulic fluid | Mineral oil |

| Stroke speed | ≤ 0,5 m/s |

| Application | Standard seal set for normal operating conditions, offers very high resistance to wear |

D2 - Axial seal ring set consisting of PTFE STEP SEALS (O-ring seal made of NBR), double scraper (polyurethane) and a PTFE Glyd ring (NBR O ring seal) on the piston | |

|---|---|

| Temperature range | -30°C to +100°C |

| Hydraulic fluid | Mineral oil, flame-retardant hydraulic fluids HFA and HFB up to +40°C |

| Stroke speed | ≤ 1 m/s |

| Application | Seal set for high sliding speeds, no stick-slip effect, higher leakage compared to D1 and D3 |

D2V - Axial seal ring set consisting of PTFE STEP SEALS (O-ring seal made of Viton) Double scraper(Viton O-ring seals) and a PTFE Glyd ring (Viton O ring seal) on the piston | |

|---|---|

| Application | Sealing set for high sliding speeds, no stick-slip effect, greater leakage than in the case of D1 and D3, for higher temperatures (+200°C) and fluids on a phosphate ester basis (HFD) |

D3 - Tandem sealing set consisting of groove ring (polyurethane) and PTFE STEP SEAL and a compact seal (NBR-PTFE) on the piston | |

|---|---|

| Temperature range | -30°C to +80°C |

| Hydraulic fluid | Mineral oil |

| Stroke speed | ≤ 0,8 m/s |

| Application | Sealing set for high loads at minimum leakage, smooth-running stroke movements |

Cylindrical forces

Tabelle : theoretische Zylinderkraft in [kN] (Wirkungsgrad = 100%)

Knickung

Grundlagen siehe „Technische Grundlagen“

Tabelle : zulässige Hübe (im elastischen Bereich) in [mm]

Knicksicherheit Sk=3,5

Bauform HZD5-H (beidseitig gelenkig gelagert —> Eulerfall 2)